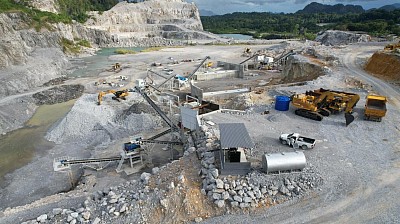

Stone Crusher Plant

Wide Distribution of Highly Abrasive Rocks Drives the Concentration of Crushing Plants in Latin America towards Cone Crushers

The Latin American aggregate industry operates on a foundation forged in fire and pressure. Across the continent, from the volcanic arcs of the Andes and the Sierra Madre to the ancient, metamorphic cores of the Brazilian Shield, quarries contend with some of the most challenging and abrasive rock formations on earth. These materials, including basalt, andesite, quartzite, and granite, are prized for their strength and durability in construction but present a formidable adversary to processing equipment. This widespread geological reality is not a minor operational footnote; it is a primary engineering and economic driver shaping the entire industry's approach to crushing. The constant battle against wear and the imperative for consistent product quality are compelling a decisive shift in equipment selection across the region. While jaw crushers remain essential for primary breaking, the heart of the modern Latin American stone crusher plant(planta de trituracion de piedra) is increasingly and unequivocally a high-performance cone crusher, specifically engineered to conquer abrasion.

The Abrasive Geology of Latin America: A Regional Operational Imperative

Understanding this equipment trend requires a look at the ground beneath. The Andes mountain chain, running the length of South America, is a product of ongoing subduction, resulting in vast deposits of igneous rocks like andesite and basalt. These rocks are exceptionally hard and possess a high Abrasion Index (AI) and low Silicon Dioxide (SiO2) content, which translates into severe, rapid wear on crushing surfaces. Similarly, regions across Central America and Mexico feature extensive volcanic belts. In Brazil and parts of the Guiana Shield, ancient quartzites and granites, while chemically different, are equally punishing due to their high quartz content. For an aggregate producer, this geology dictates a fundamental operational truth: equipment that cannot withstand abrasion will face catastrophic maintenance costs, excessive downtime, and uncontrollable fluctuations in product gradation. This makes the upfront gravel crusher price(trituradora de piedra para grava precio) a secondary consideration to the total cost of ownership, where wear part life and operational reliability are the defining metrics.

Why Cone Crushers Dominate in Abrasive Applications

In the face of such harsh feed material, cone crushers have emerged as the dominant technology for secondary and tertiary crushing stages in Latin America. Their design and operational principles offer distinct, critical advantages over alternative technologies like impact crushers when processing highly abrasive rock.

Superior Wear Part Life and Cost Management

The fundamental action of a cone crusher is compressive crushing. Rock is nipped and crushed between a rotating mantle and a stationary concave liner. This direct, progressive compression causes rock-on-rock breakage in the chamber, which to some extent protects the metal surfaces. More importantly, modern cone crushers are designed with massive, high-grade manganese steel wear liners. These liners are far thicker and more robust than the blow bars in an impact crusher. When processing abrasive Andes rock, a well-configured cone crusher can achieve liner life several times longer than an impact crusher's blow bars. This directly reduces the frequency of shutdowns for liner changes, lowers the cost-per-ton for wear parts, and dramatically improves plant availability—a crucial factor for meeting the relentless demand from Latin America's construction sector.

Unmatched Control Over Product Shape and Gradation

Consistency is king in aggregate production, especially for high-value applications like asphalt and high-strength concrete. Cone crushers excel here. Through precise hydraulic adjustment of the crusher's closed-side setting (CSS), operators can maintain a tight, consistent product size distribution even as the liners wear. Advanced models feature automated setting systems that compensate for liner wear in real-time, ensuring the final product spec remains unchanged for weeks of operation. This level of control is extremely difficult to achieve with an impact crusher processing abrasive material, where rapidly wearing blow bars quickly alter the product curve. For a fixed stone crusher plant supplying major infrastructure projects, this consistency is a key competitive advantage that justifies the investment in cone crusher technology.

High Efficiency and Lower Energy Consumption

Cone crushers are highly efficient machines. Their continuous crushing action and optimized chamber designs allow for high reduction ratios in a single pass, often reducing the need for additional crushing stages. This efficiency translates into lower energy consumption per ton of final product. In an era of rising energy costs and growing emphasis on operational sustainability, this efficiency is a significant benefit. While the initial gravel crusher price for a quality cone crusher may be higher than some alternatives, the long-term savings in power, combined with superior wear life and product control, deliver a lower total operating cost in abrasive environments.

Strategic Plant Configuration and Market Considerations

This regional preference for cone technology influences entire plant design. A typical high-production plant for abrasive rock will feature a robust jaw crusher for primary duty, feeding one or multiple cone crushers in secondary and tertiary roles. Screening is critical, with closed-circuit designs ensuring optimal feed to the cones and maximizing efficiency.

It is important to note that this trend is specific to hard, abrasive virgin rock. For applications focused on recycling construction and demolition (C&D) waste, the calculus changes. Softer materials like concrete and brick are less abrasive, and here impact crushers can be highly effective, often offering higher throughput for recycling. However, the market dynamics differ; the debris crusher price(trituradora de escombros precio) and operational logic for a recycling operation are distinct from those of a hard-rock quarry. In the vast Latin American market, where virgin aggregate from abrasive sources forms the bulk of supply, the cone crusher's value proposition is undeniable.

Conclusion: A Convergence of Geology and Engineering

The concentration of crushing plant technology towards cone crushers in Latin America is not a passing trend but a rational, enduring response to a fundamental regional condition. The widespread distribution of highly abrasive rocks has made durability, consistency, and total cost of ownership the paramount concerns for aggregate producers. Cone crushers, with their robust design, exceptional wear life, and precise control, are uniquely engineered to meet these challenges. While the initial capital outlay reflected in a gravel crusher price quote is a factor, the industry's collective experience has proven that in the long, grinding battle against Andean basalt or Brazilian quartzite, the cone crusher is the most reliable and economical champion. As Latin America continues to build its future, the plants that supply its foundational materials will increasingly rely on this proven technology to turn its toughest rock into its strongest infrastructure.

The mining and aggregate industry in Latin America is facing increasing pressure to adopt environmentally responsible practices. Governments across the region have implemented stricter environmental regulations to reduce dust, noise, and energy consumption from crushing operations. This shift has prompted manufacturers and operators to rethink traditional stone crusher plant(planta trituradora) designs and invest in greener, more sustainable solutions.

Crushing equipment such as limestone crusher units are essential for producing aggregates used in construction, road building, and industrial applications. However, conventional crushing methods can generate significant environmental impact, including particulate emissions, high energy consumption, and noise pollution. Adapting to environmental regulations not only helps companies comply with legal requirements but also enhances efficiency, reduces costs, and supports long-term sustainable development.

The Role of Environmental Regulations in Driving Change

Environmental policies across Latin America have become a key factor influencing equipment selection and plant operation. Governments are introducing stricter emission standards, dust control mandates, and noise level restrictions for mining and aggregate production sites. These regulations directly impact how stone crusher plant operators design workflows, choose machinery, and implement maintenance protocols.

For example, several countries now require crushers(precio de trituradoras de piedra) to be equipped with dust suppression systems, such as water spray nozzles or cyclone dust collectors. Noise control measures, including soundproofing enclosures and vibration dampers, have also become standard for compliance. Operators are increasingly aware that meeting these requirements is not optional—it is essential for project approval, community relations, and long-term business sustainability.

Technology Innovations in Green Crushing Equipment

1. Energy-Efficient Crushers

Modern limestone crusher designs focus on energy efficiency without compromising production capacity. Variable frequency drives, optimized rotor designs, and high-efficiency motors reduce electricity consumption while maintaining consistent crushing performance.

Energy-efficient equipment also lowers operational costs, offering a direct financial incentive alongside regulatory compliance. For large-scale stone crusher plant operations, energy savings can be significant over the equipment’s lifetime, improving return on investment while aligning with environmental goals.

2. Dust and Emission Control

Dust emissions are one of the most visible environmental concerns at aggregate production sites. Modern crushing plants incorporate advanced dust suppression systems, including enclosed conveyor belts, suction hoods, and high-pressure water sprays.

These solutions not only meet government regulations but also improve worker safety and reduce material loss. Contractors handling limestone crusher(trituradora de caliza) operations report that integrating dust collection systems increases production efficiency while minimizing environmental complaints from nearby communities.

3. Noise Reduction Measures

Noise pollution is another key environmental issue. Crushing equipment manufacturers now provide soundproof enclosures, acoustic panels, and vibration-reducing foundations to limit operational noise. Medium and large stone crusher plant units designed with these features can operate in urban or suburban areas without disturbing nearby populations.

Noise reduction is especially important for contractors working near residential zones or sensitive ecological areas, allowing projects to continue without legal interruptions or community disputes.

Green Crushing Equipment and Operational Efficiency

Adopting environmentally friendly equipment often goes hand-in-hand with improved operational efficiency. Automated control systems enable precise material handling, optimize crushing cycles, and reduce wear and tear on components.

For example, intelligent feeding mechanisms in a limestone crusher prevent overloading, reducing energy waste and extending the lifespan of critical parts. Similarly, modern conveyors and screening systems minimize material spillage, further enhancing productivity.

These efficiency improvements contribute to both sustainability and cost-effectiveness, demonstrating that environmental compliance and operational performance can go hand in hand.

Market Trends and Adoption Challenges

The demand for greener crushing equipment is rising steadily across Latin America. Contractors are increasingly seeking stone crusher plant models that combine high capacity, energy efficiency, and compliance with environmental standards.

However, challenges remain. Upfront investment costs for environmentally friendly equipment, including integrated dust and noise control systems, are higher than for traditional units. Some smaller operators hesitate due to budget constraints, despite long-term savings and regulatory compliance benefits.

Government incentives, financing options, and supplier support programs are helping to overcome these barriers. Companies that adopt green technologies early gain a competitive advantage, positioning themselves as sustainable operators in a market increasingly driven by environmental responsibility.

Future Outlook for Sustainable Crushing

Looking forward, the trend toward green crushing equipment is expected to accelerate. Manufacturers are developing hybrid solutions that combine stationary stone crusher plant capacity with mobile flexibility, further reducing transportation emissions and improving site adaptability.

Digital monitoring and automation will continue to play a major role, enabling operators to track energy usage, emissions, and maintenance requirements in real time. This data-driven approach supports ongoing compliance with evolving regulations while optimizing production processes.

As Latin America invests in infrastructure, renewable energy projects, and urban development, sustainable aggregate production will remain a critical component of the construction supply chain. Contractors that adopt energy-efficient limestone crusher technology and comply with environmental standards will benefit from improved community relations, operational savings, and long-term business resilience.

Conclusion

Government environmental regulations are reshaping the aggregate and mining industry in Latin America, driving the adoption of greener stone crusher plant solutions. Modern crushing equipment, including advanced limestone crusher units, delivers energy efficiency, dust and noise reduction, and operational improvements, meeting both regulatory and business needs.

By embracing sustainable crushing practices, contractors can achieve compliance, reduce costs, and contribute to environmentally responsible infrastructure development. As the region continues to grow, green crushing technology will play an essential role in shaping the future of Latin America’s construction and mining sectors.

Transportation Risks And Damage Prevention Measures For Crushing Plants In Latin American Mining Projects

Transporting heavy mining equipment across Latin America is a logistical challenge that requires meticulous planning and execution. Crushing plants, whether stationary or mobile, represent significant investments for mining companies. Any mishandling during transport can result in costly delays, equipment damage, or even safety hazards at the destination site. This is particularly critical when moving a stone crusher plant(planta trituradora de piedra), an aggregate crusher plant, or a mobile stone crusher plant, as their components are heavy, sensitive to vibration, and essential for continuous mining operations.

Understanding transportation risks and implementing effective damage prevention measures is essential for ensuring these plants arrive in perfect condition, ready for installation and operation.

Common Transportation Risks For Crushing Plants

Moving large-scale crushing plants in Latin America comes with unique challenges due to terrain, infrastructure, and long distances between mining projects and ports.

Vibration And Shock During Transit

The roads leading to remote mining areas often include unpaved stretches, mountain passes, and uneven surfaces. This makes equipment highly susceptible to vibration and shocks. For crushing plants with precision parts like motors, bearings, and control systems, excessive vibration can shorten lifespan or cause misalignment.

Weather And Environmental Conditions

Latin America’s varied climates—from tropical humidity in the Amazon to arid conditions in northern Chile—pose additional risks. Excessive moisture can lead to rust and corrosion of steel frames, while high dust exposure may affect sensitive control systems. Proper packaging and sealing are crucial when transporting a stone crusher plant or aggregate crusher plant(planta de agregados) across such diverse regions.

Loading And Unloading Hazards

Heavy machinery requires specialized cranes, forklifts, and trained teams for safe loading and unloading. Improper handling can lead to dents, scratches, or worse, structural damage to plant frames. These damages may not only delay project timelines but also increase repair and maintenance costs.

Theft And Security Risks

Transporting valuable machinery over long distances sometimes exposes shipments to theft or tampering. Given the high value of a mobile stone crusher plant, adequate security measures during transit are necessary to protect investments.

Preventive Measures To Reduce Damage

To ensure equipment reaches its final destination safely, mining companies and suppliers must adopt rigorous preventive measures.

Robust Packaging And Protective Materials

Every major component of a crushing plant should be secured in reinforced crates or steel frames. Shock-absorbing materials such as foam padding and vibration dampers help protect delicate parts. Anti-rust coatings and vacuum-sealed wrapping reduce the risk of corrosion in humid conditions.

Pressure-Resistant And Weatherproof Packaging

Packaging must be tested for resistance against stacking, pressure, and extreme weather during long transport journeys. This ensures equipment maintains integrity even under challenging conditions. A well-prepared aggregate crusher plant shipment can withstand impacts without compromising structural quality.

Route Planning And Transport Mode Selection

Route optimization is critical when transporting large machinery across Latin America. Selecting the right transportation mode—whether sea freight, overland trucking, or a combination of both—reduces risks and ensures timely delivery. For sites in mountainous regions, additional planning is required to avoid roadblocks, weight restrictions, or seasonal closures.

Skilled Handling Teams For Loading And Unloading

Experienced crews with the right lifting equipment are essential for safe loading and unloading. Clear documentation of handling procedures minimizes the risk of mistakes. Investing in trained personnel reduces the likelihood of structural or mechanical damage to a stone crusher plant.

Insurance And Risk Management

Comprehensive insurance coverage is another vital preventive measure. It provides financial protection against potential damages or delays caused by accidents, weather events, or logistical setbacks. Mining companies must evaluate insurance options carefully, especially when transporting a mobile stone crusher plant(planta trituradora de piedra movil) through multiple countries.

The Role Of Suppliers In Damage Prevention

Suppliers play a critical role in ensuring crushing plants are delivered safely. Reputable manufacturers not only design equipment for high performance but also implement strict quality control in packaging and shipment preparation.

For example, many suppliers conduct pre-shipment assembly and testing to ensure all components are fully functional before transport. They also provide detailed shipping diagrams and handling instructions to guide unloading teams. This level of preparation reduces the risks associated with long-distance logistics in Latin American mining projects.

Conclusion

The transportation of crushing plants in Latin America involves numerous risks, from road vibration to weather exposure and handling hazards. Without proper preparation, mining companies risk equipment damage, project delays, and increased costs. However, by adopting robust packaging, effective route planning, professional handling practices, and reliable insurance coverage, these risks can be minimized.

Whether moving a stone crusher plant, an aggregate crusher plant, or a mobile stone crusher plant, preventive measures ensure equipment arrives safely and performs reliably in mining operations. For mining companies in Latin America, prioritizing transportation safety is not only a matter of protecting assets but also a critical step in maintaining efficiency and project profitability.

Analysis Of Price Trends And Procurement Opportunities For Stone Crushing Plants In The Latin American Market

The mining and construction sectors in Latin America are experiencing steady growth, driven by infrastructure development, urbanization, and increased demand for high-quality aggregates. For contractors and investors, understanding the price trends and identifying procurement opportunities for stone crusher plant(planta de trituracion) equipment is crucial to making informed investment decisions. This article explores current market conditions, equipment options, and strategies to optimize procurement in the Latin American region.

Current Market Dynamics In Latin America

The demand for construction aggregates such as sand, gravel, and crushed stone has been rising across Latin America. Countries like Brazil, Mexico, Chile, and Peru are investing heavily in road construction, urban infrastructure, and mining projects. These activities have increased the demand for reliable crushing equipment, including aggregate crusher plant solutions and mobile stone crusher units that offer flexibility for remote or small-scale projects.

Factors Influencing Equipment Prices

Several factors contribute to price fluctuations for stone crusher plant equipment in the region:

- Raw Material Availability: Limited access to steel and other critical components can increase production costs.

- Transportation Costs: Latin America’s diverse geography can lead to higher shipping expenses, especially for heavy or stationary crushing units.

- Local Taxes and Import Duties: Import tariffs and local taxation can affect overall procurement costs, making it essential to compare domestic and international suppliers.

- Technological Upgrades: Modern equipment with intelligent control systems, energy-efficient motors, or automation features may have higher initial costs but offer long-term savings.

Mobile Versus Stationary Crushing Options

The choice between stationary and mobile crushing equipment is a key consideration for procurement:

- Stationary Aggregate Crusher Plants(planta de agregados) are ideal for large-scale, long-term projects where production capacity is prioritized. They offer high throughput and durable construction but require a permanent site and higher initial investment.

- Mobile Stone Crusher Units provide flexibility for projects located in remote or multiple sites. They reduce transportation costs of raw materials and finished aggregates, allow quicker relocation, and are increasingly popular for medium and small-scale projects.

Price Trends For Stone Crusher Plants

Over the past few years, the price of stone crusher plant equipment in Latin America has been influenced by global supply chain disruptions, inflationary pressures, and fluctuating demand. Mobile and modular solutions have seen steady demand due to their versatility, while stationary units have experienced price adjustments linked to production scale and import costs. Contractors should monitor market reports and supplier quotations to identify optimal purchase windows.

Cost-Saving Strategies

- Bulk Procurement: Investing in multiple units or modular components at once may attract discounts from manufacturers.

- Local Suppliers: Partnering with regional equipment manufacturers can reduce shipping and import fees.

- Refurbished Equipment: Carefully inspected second-hand plants can provide cost savings while meeting project requirements, particularly for small-scale operations.

- Energy Efficiency: Selecting crushers with energy-saving motors or optimized crushing technology can reduce operational costs over the plant’s lifetime.

Procurement Opportunities In Latin America

Targeted Infrastructure Projects

Latin America’s focus on road expansion, mining infrastructure, and urban development creates opportunities for aggregate crusher plant procurement. Governments and private contractors frequently release tenders for aggregate supply, offering potential buyers access to stable project-based demand.

Remote And Mobile Applications

For companies operating in areas with scattered mining sites or rural road projects, mobile stone crusher(trituradora movil de piedra) units provide a strategic advantage. Mobile units allow operators to process materials on-site, minimizing haulage and enabling faster project completion.

Financing And Leasing Options

Some suppliers in Latin America offer financing plans or equipment leasing programs to support contractors with limited capital. These options reduce upfront costs and improve cash flow, making it easier to acquire modern stone crusher plant equipment without compromising project schedules.

Practical Tips For Buyers

- Conduct a market survey to compare prices among multiple suppliers.

- Assess transportation and installation costs alongside the price of stone crusher plant.

- Evaluate the compatibility of plant features with specific project requirements, such as capacity, mobility, and automation.

- Consider after-sales support, availability of spare parts, and maintenance services to minimize operational downtime.

Conclusion

The Latin American market presents growing opportunities for contractors and investors in the stone crushing and aggregate sector. By understanding price trends and carefully assessing procurement options for stone crusher plant, aggregate crusher plant, and mobile stone crusher equipment, buyers can reduce costs, increase operational efficiency, and meet the rising demand for high-quality aggregates. Strategic investment decisions, coupled with the right equipment choice, will allow companies to remain competitive and capitalize on ongoing infrastructure development throughout the region.

Advantages Of High-Reduction Impact Crushers In Latin American Stone Production

The stone and aggregates industry in Latin America is rapidly expanding, driven by infrastructure development, urbanization, and growing demand for construction materials. High-reduction impact crushers have emerged as a vital component in modern stone production lines, offering enhanced efficiency, versatility, and output quality. These crushers are increasingly preferred for stone crusher plants(planta trituradora) and aggregate crusher plants, especially when consistency and fine particle control are critical. Understanding the advantages of high-reduction impact crushers helps mining operators optimize production and reduce operational costs.

Understanding High-Reduction Impact Crushers

High-reduction impact crushers are designed to crush stones and rocks by using high-speed impact energy rather than compression. Unlike traditional jaw or cone crushers, these machines accelerate the feed material to a high velocity and then impact it against hammers, blow bars, or impact plates. This process allows for greater reduction ratios, producing finer and more uniform aggregates.

In Latin American stone production lines, high-reduction impact crushers are used both in stationary aggregate crusher plants(planta de agregados) and mobile stone crusher setups. Their ability to handle a wide range of rock types, from limestone to basalt, makes them highly adaptable for different production requirements. They are particularly suitable for secondary and tertiary crushing stages, where precision and output consistency are essential.

Benefits Of High-Reduction Impact Crushers

Enhanced Efficiency And Output

High-reduction impact crushers offer significant improvements in efficiency compared to traditional crushers. Their design allows for continuous feed and high throughput, making them ideal for large-scale stone crusher plants. The ability to achieve high reduction ratios in a single pass reduces the need for multiple crushing stages, which saves energy and lowers operational costs.

Uniform And High-Quality Aggregate

One of the main advantages of high-reduction impact crushers is their ability to produce uniform particle shapes. This is essential for construction applications such as concrete, asphalt, and road base materials. Consistent aggregate shapes improve compaction, strength, and durability in downstream applications. In Latin America, where infrastructure projects demand high-quality materials, this feature provides a clear competitive edge.

Versatility For Different Materials

These crushers are highly versatile and can process a wide variety of stone types and sizes. They are capable of handling soft and medium-hard rocks like limestone as well as harder rocks such as granite. This flexibility allows mining operators to switch between different materials without extensive equipment changes, optimizing production across various project requirements.

Reduced Operational Costs

High-reduction impact crushers often feature wear-resistant components, such as hammers and blow bars, which extend service life and reduce maintenance costs. Additionally, the high efficiency of these machines means fewer units are needed in the crushing line, lowering energy consumption and labor requirements. For mobile stone crusher(trituradora de piedra movil) units, this translates to cost-effective operations even in remote or challenging locations.

Applications In Latin American Stone Production

Latin America’s growing construction sector has created a demand for efficient and adaptable aggregate production solutions. High-reduction impact crushers are widely used in both stationary aggregate crusher plants and mobile stone crusher setups to meet this demand. Mobile units, in particular, provide flexibility for projects in remote areas or sites with limited infrastructure, enabling on-site production and reducing transportation costs.

In addition, many Latin American stone production facilities integrate high-reduction impact crushers into multi-stage crushing lines to produce high-quality sand and aggregates. Their ability to handle varying feed sizes and material hardness makes them essential for producing construction-grade materials for roads, bridges, and commercial buildings.

Conclusion

High-reduction impact crushers offer numerous advantages for Latin American stone production lines, including enhanced efficiency, uniform and high-quality aggregate, versatility for different materials, and reduced operational costs. Whether used in stationary stone crusher plants, aggregate crusher plants, or mobile stone crusher setups, these machines help mining operators meet the growing demand for high-quality construction materials.

By investing in high-reduction impact crushers, Latin American stone producers can streamline operations, improve material quality, and reduce overall production costs. Their adaptability, efficiency, and reliability make them a critical component of modern stone production lines and a strategic choice for construction-focused mining operations across the region.

How Integrated Design Reduces Safety Risks During the Construction and Transfer of Stone Crusher Plants

In the fast-paced world of mining and infrastructure development, stone crusher plants are frequently relocated, upgraded, or expanded to match changing project demands. These transitions—whether during initial setup or when transferring the plant to a new site—introduce serious safety risks for operators, technicians, and logistics personnel. Fortunately, integrated design is emerging as a powerful solution to minimize these risks. By incorporating mechanical, electrical, and structural systems into a unified framework, integrated design enhances safety at every stage of the plant's lifecycle. This article explores how integrated design contributes to safer construction and transfer of crushing plants, including stone crusher units, debris crushers, and concrete crushers.

What Is Integrated Design in Crushing Plants?

Integrated design refers to the holistic engineering of a system where various components—such as crushers, conveyors, feeders, and control panels—are built to work together seamlessly. In a stone crusher plant(planta de trituracion de piedra), this means standardized modular components, shared structural supports, coordinated power layouts, and central control systems are all planned together from the outset.

Unlike traditional setups that rely on assembling parts from different manufacturers on-site, an integrated design ensures compatibility, simplifies installation, and reduces on-site modifications. For operations involving a debris crusher or concrete crusher, this level of integration directly reduces the number of manual interventions and error-prone adjustments.

Safety Benefits During Initial Construction

Simplified Assembly and Fewer On-Site Adjustments

One of the main causes of accidents during stone crusher plant construction is the need for manual assembly and on-the-fly adjustments. With integrated design, equipment is delivered in modular form, often pre-wired and pre-tested. This significantly reduces the time technicians spend working at height, inside confined spaces, or around heavy equipment under construction.

Fewer manual alignments also mean less use of temporary tools like cranes, jacks, or welding gear, each of which introduces specific safety risks. For debris crusher(trituradora de escombros precio) installations in urban or restricted areas, modular units can be deployed faster with less disruption to surrounding environments.

Optimized Structural Supports and Foundations

Integrated design takes into account load balancing and dynamic forces across the entire plant. Proper alignment between crushers, conveyors, and hoppers minimizes vibration and mechanical stress. This reduces the risk of structural failure, especially when deploying high-force machines like a concrete crusher.

Prefabricated steel frames and foundation plans developed in the design stage eliminate guesswork during construction, ensuring each part is securely mounted and stable from the start.

Safety Improvements During Transfer and Relocation

Reduced Equipment Handling

When a stone crusher plant is designed with relocation in mind, the number of lifting operations and reassembly steps is significantly reduced. For example, crushers and screens may be mounted on a single transportable chassis with foldable walkways, reducing crane usage and manual bolting at the new site.

In mobile or semi-mobile setups, integrated design ensures that components like motors, gearboxes, and dust control systems are housed in shock-proof modules. This reduces the risk of damage or misalignment during transportation, which can otherwise lead to failures upon reinstallation.

Standardized Cable and Hose Routing

Transferring a traditional stone crushing plant often involves rewiring electrical panels, re-routing hydraulic hoses, and reconnecting sensors manually—each of which poses fire, electrocution, or mechanical hazard risks. Integrated design consolidates all connections into protected channels and junctions, often color-coded or labeled for fast, error-free reassembly.

This is especially useful for complex machines like a concrete crusher(trituradora de hormigón) with multiple control inputs and safety interlocks, as it eliminates trial-and-error during setup.

Enhanced Operator Safety and Maintenance Access

Centralized Control and Emergency Shutdown Systems

Integrated plants typically include a centralized control unit with emergency shutdown switches that cover the entire operation. In the event of an incident—such as a blockage in the debris crusher or overheating in the motor system—operators can respond immediately without running across the site.

Some systems also include remote diagnostics, allowing technicians to troubleshoot issues without opening panels or entering restricted areas, further improving safety during both routine checks and emergencies.

Safer Maintenance and Inspection Procedures

Integrated platforms provide standardized access points, handrails, lighting, and walkways around major components. Regular maintenance tasks such as jaw liner changes, oil checks, or belt alignments can be carried out without temporary scaffolding or ladders.

This is a major improvement for mobile stone crusher units, which previously required makeshift arrangements for accessing elevated or enclosed parts of the machinery. Safer access directly reduces falls, slips, and crush injuries.

Reducing Environmental and Site Hazards

Dust and Noise Control Integration

Dust suppression and noise insulation systems are often treated as afterthoughts in traditional plant layouts. Integrated design, however, includes these safety elements from the beginning. Water spray systems, enclosures, and acoustic barriers are positioned optimally, reducing airborne particles and harmful noise exposure.

This is particularly critical when operating in environmentally sensitive areas or near urban developments, where regulatory compliance is essential.

Efficient Footprint and Traffic Flow Planning

Finally, integrated design considers the overall layout of the stone crusher plant in relation to site logistics. Clear pathways for trucks, loaders, and maintenance staff help reduce the risk of vehicle collisions or pedestrian injuries. When debris crushers and concrete crushers are included in the same system, optimized traffic flow ensures materials and personnel do not cross paths unnecessarily.

Conclusion

Integrated design is transforming the way stone crusher plants are built, moved, and maintained—particularly in high-risk sectors like mining and infrastructure construction. By streamlining equipment compatibility, minimizing manual adjustments, and embedding safety into every layer of the system, integrated design reduces accidents and increases operational efficiency. Whether using a compact debris crusher for urban demolition or a full-scale aggregate stone crusher plant for a large quarry, adopting an integrated approach is one of the most effective ways to ensure a safer and more productive job site.

The Working Principle of Each Stage of Equipment in a Stone Crusher Plant

A stone crusher plant is an essential part of the mining and aggregate industry, designed to process large volumes of raw materials into smaller, usable products like gravel, sand, and crushed stones. The equipment used in these plants operates in various stages to ensure that the final product meets the required specifications. In this article, we will explore the working principles of the equipment used in each stage of a stone crusher plant, highlighting the role of each component in transforming raw materials into valuable construction aggregates.

1. Primary Crushing: The Jaw Crusher

The first stage of the stone crushing process(planta de trituracion de piedra) is primary crushing. At this stage, large rocks or materials are reduced to a manageable size for further processing. The jaw crusher is typically used for primary crushing in stone crusher plants due to its ability to handle large, tough materials efficiently.

a. How the Jaw Crusher Works

A jaw crusher operates on the principle of compression. It consists of two jaws—one fixed and one movable. The material is fed into the crusher, and as the movable jaw closes, it compresses the material against the fixed jaw. This force breaks down the material into smaller pieces, which are then discharged from the bottom of the crusher. Jaw crushers are ideal for processing materials like granite, limestone, and other hard stones. The output from this stage is typically larger, more jagged material that requires further processing.

2. Secondary Crushing: The Cone Crusher

Once the material has been crushed in the primary stage, it moves on to secondary crushing. This stage further reduces the material to a more refined size and is often done using a cone crusher. The cone crusher is effective at producing smaller, more uniform aggregates, making it essential for producing materials suitable for concrete production and other construction applications.

a. How the Cone Crusher Works

The cone crusher operates using a rotating mantle and a stationary concave. As the material enters the crusher, the mantle rotates, compressing and crushing the material against the concave. This reduces the size of the material and ensures a more uniform output. Pebble crushers(trituradora de piedra de rio), which are a type of cone crusher, are often used in mining operations where materials like pebbles and small stones need to be crushed further into finer sizes.

b. Benefits of Secondary Crushing

Secondary crushing with a cone crusher results in finer material and reduces the need for additional stages of processing. This is particularly important when producing aggregates for specific uses, such as concrete crusher applications, where consistency in size and shape is crucial.

3. Tertiary Crushing: The Impact Crusher

After the secondary crushing stage, the material may still need to be further refined. Tertiary crushers, typically impact crushers, are used to produce smaller, more uniform particles that are suitable for specialized applications, including asphalt production or fine aggregates.

a. How the Impact Crusher Works

The impact crusher operates by using high-speed rotors with blow bars that strike the material, causing it to break into smaller particles. This method is ideal for producing fine aggregates and is highly effective for softer materials. Impact crushers are versatile and can handle a wide range of materials, from soft rocks like limestone to harder stones, making them an essential part of the crushing process in stone crusher plants.

b. Benefits of Tertiary Crushing

Tertiary crushing further improves the quality of the aggregates produced by reducing the size of particles and creating a more uniform texture. This stage is especially important when producing materials like sand or fine gravel, which are commonly used in concrete crusher(trituradora de concreto) applications and other industries requiring precise particle sizes.

4. Screening and Washing

Once the material has been crushed to the desired size, it is passed through screening equipment to separate the different sizes of aggregates. Screening is essential to ensure that the final product meets the specifications for various construction applications.

a. How Screening Works

In a stone crusher plant, screens are used to sort the crushed material by size. Vibrating screens are commonly employed, with multiple layers that allow different-sized particles to pass through. The larger material remains on the top screen, while the smaller material falls through to the next layer. The material is then categorized into various size fractions for use in different construction processes.

b. The Role of Washing

In some cases, washing equipment is used to clean the aggregates. This is particularly important for materials like sand and gravel, which may have clay or dirt mixed in. Washing removes impurities, ensuring that the final product meets the quality standards required for high-end applications, such as concrete production.

Conclusion

The working principle of each stage of equipment in a stone crusher plant plays a critical role in ensuring that the final product meets the required specifications for construction and aggregate industries. From the primary jaw crusher to secondary cone crushers, and tertiary impact crushers, each piece of equipment works together to break down and refine raw materials into usable aggregates. Screening and washing further enhance the final product, making it suitable for various construction applications.

By understanding the workings of each stage, operators can make more informed decisions when selecting the equipment for their stone crusher plant, ensuring that the production process is efficient and cost-effective. Whether you are processing hard stones like granite or softer materials for concrete crusher applications, selecting the right crushers and auxiliary equipment is key to the success of your plant operations.

Does the Installation Site Space Affect the Selection of Stone Crushing Plant Equipment?

When planning to invest in a stone crusher plant, one of the most overlooked yet critical factors is the available space at the installation site. Whether you're working in a wide open quarry or a confined urban project, space limitations can significantly impact equipment choices, layout design, and even production efficiency. In the mining and aggregate industry, optimizing equipment selection based on the site footprint is not just about convenience—it’s about cost, productivity, and long-term success.

Why Installation Space Matters in Crushing Plant Design

A well-planned installation site can boost efficiency, reduce material handling costs, and ensure safety. On the other hand, poor space planning can lead to operational issues, increased downtime, and unnecessary equipment changes.

In reality, not every project offers a spacious location. Many aggregate producers work in mountainous regions, narrow valleys, or construction zones where space is at a premium. In such cases, compact and efficient solutions become essential.

Key Considerations When Space Is Limited

1. Equipment Footprint and Portability

In restricted spaces, compact equipment is often the go-to solution. Mobile or modular stone crusher plants(planta trituradora) are designed for quick setup and easy relocation, making them ideal for space-constrained environments. These systems reduce the need for massive concrete foundations and lengthy installation timelines.

Some mobile crushers, including concrete crushers, combine several stages of crushing and screening in a single unit, minimizing the required footprint while maintaining output capacity.

2. Plant Layout Optimization

Proper equipment layout is crucial to making the most of limited space. This includes strategic positioning of crushers, feeders, conveyors, and stockpiles. Efficient layout minimizes material travel distance, prevents congestion, and allows easy access for maintenance. For instance, an aggregate plant(planta de áridos) situated in a narrow site may use vertical stacking of conveyors or compact screening units to conserve space without sacrificing performance.

3. Equipment Type and Function Integration

In confined sites, selecting multi-functional equipment can significantly improve space efficiency. Combination units that integrate jaw crushers, cone crushers, and vibrating screens reduce the need for multiple standalone machines.

A modern concrete crusher(trituradora de concreto) might include onboard screening systems, dust suppression, and material conveyors, streamlining the operation and minimizing ground area requirements.

4. Power and Infrastructure Planning

Limited space can also affect the placement of electrical systems, water sources, and fuel storage. It’s important to consider how these utilities will be routed around the equipment without causing obstructions or creating safety hazards.

When selecting equipment for a tight site, opting for systems with reduced infrastructure dependency—such as mobile units with built-in generators—can be a smart move.

5. Compliance and Safety

Space constraints should never compromise safety. Crushing equipment must be accessible for inspection, cleaning, and repair. Adequate spacing is also required to meet industry safety standards regarding operator walkways, emergency exits, and dust control zones.

A compact stone crusher plant that’s specifically engineered with safety in mind can offer both space efficiency and regulatory compliance.

Benefits of Matching Equipment to Site Space

Choosing crushing equipment based on available space brings several operational and financial advantages:

- Reduced installation costs: Smaller equipment requires less site preparation and civil work.

- Faster commissioning: Mobile or modular units can be set up and made operational quickly.

- Improved flexibility: When the plant needs to be relocated or upgraded, space-efficient systems simplify the process.

- Higher productivity in constrained zones: Optimized layouts lead to smoother material flow and fewer bottlenecks.

Conclusion

The installation site space plays a decisive role in determining the ideal configuration of a stone crusher plant. From footprint limitations to layout challenges and infrastructure planning, understanding the constraints of your project site is essential for making smart equipment decisions.

For operations in tight areas, compact and integrated crushing solutions—such as mobile or modular aggregate plant systems—offer the flexibility and performance needed to meet production targets. Whether you're processing hard rock or recycled material with a concrete crusher, the key is to match your crushing plant design to the unique demands of your site.

Always consider space as a core factor—not an afterthought—when planning a crushing operation. Doing so will help you avoid delays, reduce costs, and maintain safe, efficient production in any environment.

How to Choose Screening Equipment in Stone Crusher Plant?

Selecting the right screening equipment is essential for ensuring the efficiency and productivity of a stone crusher plant. Proper screening helps separate materials of different sizes, improving the final product quality while reducing waste. The right choice depends on material characteristics, processing capacity, and application requirements. This article explores key factors to consider when choosing screening equipment in an aggregate crusher plant.

Understanding the Role of Screening in a Stone Crusher Plant

Screening is a crucial step in aggregate production. It separates crushed materials into different sizes before further processing or final use. A well-optimized screening system enhances productivity by ensuring that oversized materials are sent back for re-crushing while the required sizes move forward. Whether used with a cone crusher for secondary crushing or as a final step in material refinement, effective screening improves overall stone crusher plant(como funciona una planta trituradora de piedra) efficiency.

Factors to Consider When Choosing Screening Equipment

1. Type of Material and Particle Size

The type of material being processed determines the required screening efficiency. Hard rocks, such as granite and basalt, require robust screens with durable mesh to withstand high impact. Softer materials, like limestone, may work well with standard screens. Additionally, knowing the expected particle size distribution helps select screens with the right mesh openings to achieve the desired separation.

2. Screening Capacity Requirements

Each stone crusher plant has different production targets. The screening equipment must handle the plant’s capacity without causing bottlenecks. High-capacity operations require multi-deck vibrating screens, while smaller applications may use single-deck screens. Matching screening capacity with crusher output ensures smooth workflow and prevents unnecessary downtime.

3. Screening Technology Options

Several types of screening equipment are commonly used in an aggregate crusher plant(planta trituradora de agregados), each with distinct advantages:

- Vibrating Screens: The most widely used for aggregates, offering high efficiency and precise separation.

- Trommel Screens: Suitable for screening fine and wet materials, though not as common in stone crushing.

- Inclined Screens: Provide a larger screening area and efficient stratification for high-volume production.

- Horizontal Screens: Ensure better control over the screening process, often used with fine materials.

Choosing the right type depends on the plant layout, material type, and required throughput.

Integration with Crushing Equipment

1. Compatibility with Cone Crusher and Other Crushers

When working with a cone crusher(chancadora de cono), selecting a screen that effectively handles the secondary or tertiary crushed material is essential. Cone crushers produce finer aggregates, requiring screens with smaller mesh sizes to ensure proper classification. Similarly, for plants with jaw crushers as primary crushers, larger screens may be necessary to sort coarser materials before secondary crushing.

2. Adjustability and Scalability

A well-chosen screening system allows for adjustments based on project demands. Modular screens with replaceable mesh panels provide flexibility for handling different materials and adapting to production changes without significant downtime.

Maintenance and Durability Considerations

1. Wear Resistance and Lifespan

Since screening equipment operates under continuous vibration and load, durability is a key factor. Opt for screens made from high-quality steel or polyurethane materials to withstand wear and reduce replacement frequency. Ensuring proper lubrication and tensioning of screen components extends lifespan and minimizes downtime.

2. Easy Maintenance and Accessibility

Screening equipment should allow for easy access to replace worn-out parts like screen mesh and vibration motors. Choosing designs with quick-change features improves maintenance efficiency and reduces plant downtime, keeping production running smoothly.

Conclusion

Selecting the right screening equipment is vital for optimizing the performance of a stone crusher plant. By considering factors like material type, capacity, screening technology, and compatibility with crushers such as a cone crusher, operators can enhance efficiency and ensure high-quality aggregate production. A well-integrated screening system in an aggregate crusher plant not only boosts productivity but also reduces operational costs, making it a critical investment for long-term success.

Common Problems and Solutions in Crushing Plant Operation

Operating a stone crushing plant requires careful planning, execution, and ongoing maintenance to ensure optimal efficiency. While crushers are essential for reducing materials to the desired size, the plant faces various challenges that can affect its performance and productivity. Addressing these challenges promptly is crucial for maintaining smooth operations and minimizing downtime.

In this article, we explore the common problems that occur in stone crushing plants and the solutions that can help ensure seamless operations. Whether dealing with equipment malfunctions, material flow issues, or maintenance problems, understanding how to tackle these obstacles is key to a successful crushing operation.

1. Blockages and Jamming of Crushers

Problem:

One of the most common issues in a stone crushing plant(planta de trituracion de piedra) is blockages or jamming of crushers. This happens when oversized material or foreign objects enter the crushing chamber, causing a sudden halt in the processing. Blockages often result from inconsistent material feeding or poor material separation.

Solution:

To prevent jamming, operators can implement the following measures:

- Use of grizzly feeders: Grizzly feeders can help separate larger materials before they reach the crusher, ensuring that only the appropriately sized material enters the crushing chamber.

- Regular maintenance: Conduct routine checks and cleaning to ensure the crushers are free from foreign objects or accumulated debris.

- Proper feeding techniques: Ensuring a consistent and controlled feed rate helps prevent material overload and blockages.

Proper maintenance of crushers and feed systems significantly reduces the risk of blockages and jamming.

2. Wear and Tear of Crusher Components

Problem:

Crushing equipment, particularly the gravel crusher(trituradora grava), experiences significant wear and tear over time. The crushing chamber, hoppers, and liners can degrade, resulting in inefficient material processing, poor output quality, and frequent repairs. This can be particularly problematic in high-production environments where heavy machinery operates for long periods.

Solution:

To mitigate wear and tear, consider these strategies:

- Use high-quality materials for wear-resistant parts: Components such as liners, jaws, and hoppers should be made of durable materials like manganese steel or alloyed steel to withstand impact and abrasion.

- Regular inspection and part replacement: Schedule routine inspections and replace worn parts before they cause severe damage to other equipment.

- Adjust crusher settings: Regularly adjust the crusher’s settings to match the characteristics of the material being processed, reducing unnecessary strain on the components.

Proper maintenance and material selection play a crucial role in extending the lifespan of crushers and minimizing downtime.

3. Inconsistent Material Feed

Problem:

An inconsistent material feed can disrupt the smooth operation of a stone crushing plant. If the material is either too dry, too wet, or not uniform in size, it can cause uneven wear on equipment, lower production rates, and even result in poor-quality aggregates.

Solution:

Addressing material feed issues requires a combination of proper techniques and equipment:

- Use of feeders with adjustable flow rates: Vibrating or apron feeders that allow for precise control over the material feed rate can help ensure consistent flow.

- Material conditioning: If the material is too wet or sticky, it can be dried or pre-screened before being fed into the crusher to reduce clogging.

- Proper material separation: Using screening or sorting equipment before the crushing stage helps ensure that the material is of uniform size, reducing strain on the crusher.

By ensuring a uniform and controlled material feed, crushing efficiency and product quality can be greatly improved.

4. Vibration and Noise Issues

Problem:

Excessive vibration and noise can be common issues in a stone crushing plant. These vibrations can damage equipment, especially crushers, and also create a hazardous work environment for operators. The noise generated by crushers and other heavy equipment can exceed safe levels, causing hearing damage and contributing to fatigue.

Solution:

To reduce vibration and noise, consider the following measures:

- Installation of vibration dampeners: Rubber pads or springs can be used beneath crushers and other heavy machinery to absorb vibrations.

- Proper foundation setup: A stable foundation, free from cracks or loose materials, can help reduce excessive vibrations during operation.

- Noise barriers and enclosures: Installing sound barriers around high-noise equipment or enclosing crushers can significantly reduce the environmental impact of noise pollution.

Regularly checking for excess vibration and noise levels helps ensure that the plant operates in a safer and more comfortable environment.

5. Overloading and Equipment Failure

Problem:

Overloading occurs when the crushing plant processes more material than it can handle, leading to potential damage to crushers, conveyors, and other components. Overloading may occur due to insufficient operator awareness, improper feeding techniques, or equipment malfunction.

Solution:

To prevent overloading, plant operators should:

- Install load monitoring systems: These systems can detect when the crusher is approaching its maximum capacity and alert operators to reduce the material flow.

- Use overload protection systems: Many modern crushers come equipped with automatic overload protection to prevent damage caused by excessive loads.

- Train operators: Ensure that operators are trained to recognize signs of overloading and to adjust material feed rates accordingly.

By preventing overloading, crushing operations can remain efficient and minimize equipment failure.

6. Power and Electrical Issues

Problem:

Power and electrical issues are another common problem in stone crushing plants. Fluctuating voltage, inadequate power supply, or faulty wiring can cause machinery to malfunction, resulting in costly downtime.

Solution:

To address power-related issues:

- Invest in high-quality electrical components: Use robust wiring, transformers, and circuit breakers designed to handle the heavy demands of the crushing plant.

- Regular electrical system inspections: Conduct regular maintenance to ensure that the power supply system is functioning properly and prevent unexpected failures.

- Install power backup systems: Consider investing in backup generators or power inverters to maintain operations during power outages.

Ensuring the reliability of electrical systems is essential to preventing interruptions and ensuring smooth plant operation.

Conclusion

The successful operation of a stone crushing plant depends on timely identification and resolution of common problems that arise. Whether it’s addressing wear and tear, material feed issues, vibration, or power problems, plant operators must be proactive in maintaining equipment and ensuring smooth processes. By implementing preventive maintenance practices, improving material flow, and using advanced technologies, the crushing plant can achieve higher efficiency, reduce downtime, and enhance overall productivity.

With the right strategies and regular monitoring, these common issues can be minimized, ensuring that the gravel crusher and other equipment continue to perform at their best.

Mobile Crushers Facilitate On-Site Aggregate Production

The growing demand for aggregates in construction and infrastructure projects has led to a significant shift in how materials are processed. Traditionally, aggregate production required transporting raw materials to a fixed crushing plant. However, advancements in technology have made mobile crushers a popular solution for on-site aggregate production. These machines provide a versatile, cost-effective, and efficient method for processing materials directly at construction sites or mining operations. In this article, we will explore how mobile stone crushers facilitate on-site aggregate production and the benefits they offer.

The Rise of Mobile Crushers in the Aggregate Industry

In recent years, mobile crushers(trituradora de piedra movil have become an essential part of the aggregate industry. With the ability to crush materials on-site, these machines eliminate the need for transporting raw materials to fixed plants. Mobile crushers are typically mounted on wheels or tracks, allowing them to easily move around construction sites, quarries, and even remote locations.

1. On-Site Aggregate Processing

One of the key benefits of mobile stone crushers is their ability to process aggregates directly at the source. Rather than hauling raw materials to a centralized processing plant, construction companies can use mobile crushers to convert materials into usable aggregates on-site. This process significantly reduces transportation costs and minimizes the environmental impact associated with long-haul trucking.

2. Efficient Material Handling

Mobile crushers are designed to handle a wide range of materials, including rock, stone, concrete, and asphalt. These crushers can process materials of varying sizes, making them ideal for producing different types of aggregates. The efficiency of mobile crushers enables continuous production, which enhances productivity and reduces downtime.

3. Adaptability to Various Construction Needs

Whether working on a road construction project, demolition site, or mining operation, mobile crushers offer the flexibility to process materials according to project specifications. The equipment can be used to produce various types of aggregate sizes, such as crushed stone, sand, and gravel, ensuring that the right materials are available for different stages of construction.

Key Components of a Mobile Aggregate Crushing Plant

A mobile aggregate crushing plant(planta trituradora de agregados) is typically comprised of several key components that work together to provide efficient and high-quality aggregate production. These components include:

1. Crusher Unit

The core of a mobile stone crusher is the crushing unit, which may be equipped with different types of crushers, including jaw crushers, impact crushers, or cone crushers. The choice of crusher depends on the type of material being processed and the desired final output size.

2. Feeding System

Mobile crushers are equipped with feeding systems, such as vibrating feeders or hoppers, to move raw materials into the crushing chamber. This system ensures a consistent flow of material, preventing blockages and enhancing the overall crushing efficiency.

3. Screening Equipment

To produce different grades of aggregate, mobile crushers often include screening equipment. These screens separate materials based on size, ensuring that only the desired particle size is processed further. Screens can be adjusted to create multiple aggregate sizes for various applications.

4. Conveying System

After the material is crushed and screened, it is transported to stockpiles or directly to the desired location using conveyor belts. The conveying system in a mobile aggregate crushing plant is essential for efficient material handling, reducing the need for manual labor and minimizing material loss.

5. Power System

Mobile crushers are equipped with a power system that drives all the components, including the crusher, feeder, screen, and conveyor. Some mobile crushers are diesel-powered, while others may use electric power, depending on the site’s energy availability.

Benefits of Using Mobile Crushers for Aggregate Production

1. Cost Savings

One of the most significant advantages of using mobile stone crushers for aggregate production is the reduction in operational costs. By eliminating the need for transporting raw materials to fixed crushing plants, companies can save on fuel, labor, and equipment maintenance costs. Additionally, mobile crushers reduce the need for large stockpiles of raw material, helping to optimize space on construction sites.

2. Increased Productivity

The flexibility and mobility of mobile aggregate crushing plants allow them to operate efficiently and continuously. With minimal downtime between loading and processing, these crushers can produce large quantities of high-quality aggregates in a short period. This increases the overall productivity of construction and mining projects, ensuring timely project completion.

3. Reduced Environmental Impact

By reducing the need for transportation and processing at fixed plants, mobile crushers significantly lower the carbon footprint associated with aggregate production. Less trucking means fewer emissions, and on-site processing eliminates the environmental impact of transporting materials over long distances.

4. Improved Safety

Mobile crushers are designed with safety features to protect operators and workers on the site. The compact design and ease of operation reduce the risk of accidents compared to traditional stationary plants. Operators can monitor the crushing process from a distance, ensuring safety and minimizing exposure to hazardous conditions.

5. Flexibility and Scalability

Mobile stone crushers can be easily transported and set up at different locations, making them ideal for projects that require flexibility. Whether for a temporary construction site or a long-term mining operation, these machines can be quickly adapted to meet the specific needs of any project. Moreover, mobile crushers can be scaled to handle larger operations as required, providing the versatility needed to keep up with growing demands.

Conclusion

Mobile crushers play a crucial role in facilitating on-site aggregate production. They offer significant advantages, including cost savings, increased productivity, and reduced environmental impact. By integrating advanced technology and versatile design, mobile aggregate crushing plants allow construction companies to produce high-quality aggregates directly at the source. Whether working on a construction site, demolition project, or quarry, mobile crushers offer a flexible, efficient, and sustainable solution to aggregate production. As the demand for aggregates continues to rise, mobile crushers are sure to remain a vital component of the construction and mining industries.

What Equipment is Used for Construction Waste Recycling?

Construction waste recycling has become an essential part of the modern construction industry. As the need for sustainable development grows, the recycling of materials from demolished buildings and structures has gained significant importance. Recycling construction waste not only reduces environmental impact but also saves resources, contributing to more efficient and cost-effective projects. In this blog post, we will explore the key equipment used in the recycling of construction debris and how it is transforming the industry.

The Importance of Construction Waste Recycling

The construction industry generates a vast amount of waste, including concrete, bricks, metal, wood, and other debris. Traditional disposal methods, such as landfilling, not only waste valuable resources but also create environmental challenges, such as soil contamination and air pollution. By recycling construction waste, valuable materials can be reused, and the carbon footprint of new construction projects can be reduced.

Benefits of Recycling Construction Waste

- Resource Conservation: Recycling allows the reuse of materials like concrete, asphalt, and metal, reducing the need for raw materials.

- Cost Savings: Recycled materials are often cheaper than new materials, reducing project costs.

- Environmental Protection: Reducing waste sent to landfills helps minimize pollution and promotes sustainable construction practices.

Key Equipment for Construction Waste Recycling

To effectively recycle construction waste, specialized equipment is needed to break down, sort, and process materials. These machines are designed to handle the tough nature of construction debris, turning it into reusable aggregates and other materials. Below are the main types of equipment used for recycling construction waste.

1. Mobile Stone Crusher Plant

A mobile stone crusher plant(planta de trituracion movil) is one of the most commonly used pieces of equipment in construction waste recycling. These plants are designed for on-site crushing of materials like concrete, asphalt, bricks, and other debris. The mobile design allows them to be moved easily from one site to another, making them ideal for demolition and construction sites where waste needs to be processed immediately.

How It Works:

- Crushing: The mobile stone crusher plant crushes large chunks of construction waste into smaller, more manageable pieces. The material is then sorted for further processing.

- Screening: After crushing, the materials pass through a screening system that separates fine aggregates, such as sand, from larger debris. This ensures that the recycled material meets the necessary specifications for reuse.

The versatility and portability of mobile stone crusher plants make them indispensable for recycling large volumes of construction waste.

2. Debris Crusher

A debris crusher is a powerful machine used specifically for breaking down construction debris, such as concrete, asphalt, and brick, into smaller, reusable pieces. These crushers can handle materials of varying sizes and are equipped with powerful motors that can break through tough construction waste.

Features of Debris Crushers:

- High Crushing Power: Debris crushers are designed to handle the toughest materials, including reinforced concrete and metal.

- Adjustable Settings: Many debris crushers have adjustable settings to control the size of the output material, making them highly customizable for different recycling needs.

- Durability: Built to withstand harsh conditions, debris crushers(trituradora de escombros) are highly durable, requiring less maintenance compared to other types of equipment.

Debris crushers are a key piece of machinery for recycling concrete and other construction debris, enabling contractors to produce high-quality recycled aggregates.

3. Screening Equipment

After crushing and shredding, the next step in the recycling process is sorting the materials by size. Screening equipment plays a crucial role in this stage. Screens are used to separate different sizes of debris, ensuring that only usable materials are sent to the next processing stages.

Types of Screening Equipment:

- Vibrating Screens: These screens use vibration to separate fine particles from larger materials. They are commonly used in mobile plants for screening aggregates.

- Rotary Screens: These are used for screening large quantities of mixed debris, and they rotate to separate materials based on their size.

Screening ensures that the final recycled product meets the desired specifications and is suitable for reuse in new construction projects.

4. Shredders

Shredders are used to reduce the size of large materials such as wood, plastics, and metals found in construction waste. These machines break down tough debris into smaller, manageable pieces, making it easier to separate the recyclable materials from non-recyclable ones.

Types of Shredders:

- Single-Shaft Shredders: Ideal for shredding materials like wood, plastics, and rubber found in construction waste.

- Two-Shaft Shredders: These are more powerful machines used for shredding tough materials such as concrete and asphalt.

Shredders help improve the efficiency of the recycling process by reducing the size of materials before further processing.

5. Magnetic Separators

Magnetic separators are used to remove metal debris from construction waste. Metals, such as steel and iron, can be easily separated using magnets, which ensures that valuable materials are not wasted and can be recycled separately.

Benefits of Magnetic Separators:

- Efficient Separation: They quickly and effectively separate ferrous metals from other debris, improving the purity of the recycled materials.

- Cost-Effective: By recycling metals, construction companies can save on the cost of purchasing new materials.

Magnetic separators are essential for ensuring that all recyclable materials are properly sorted during the recycling process.

Conclusion

The recycling of construction waste is an essential practice for promoting sustainability and reducing the environmental impact of construction projects. With the use of advanced equipment such as mobile stone crusher plants, debris crushers, shredders, and screening systems, construction companies can process waste materials efficiently and turn them into valuable resources. By investing in the right equipment, companies not only help the environment but also save on costs, making recycling a win-win solution for the industry.

As the demand for sustainable construction practices grows, so too will the need for more efficient and effective recycling equipment. The evolution of technology ensures that construction waste recycling will continue to be an integral part of the future of the industry.

What Kind of Stone Crushing Plant Configuration Is Reasonable?

When setting up a stone crushing plant, one of the most important decisions you will make is determining the right configuration. A well-designed stone crusher plant not only increases productivity but also reduces operating costs and ensures the quality of the final product. The configuration of a stone crushing plant depends on various factors, including the type of material to be processed, the production capacity, and the intended use of the final product. In this article, we will explore the key elements that contribute to a reasonable stone crushing plant(planta trituradora de piedra en venta) configuration.

Key Elements of a Stone Crushing Plant Configuration

1. Material Type and Characteristics

The type of stone or material you plan to crush plays a significant role in determining the configuration of your crushing plant. For example, hard stones like granite or basalt require more powerful crushers and heavier-duty equipment compared to softer materials like limestone or sandstone.

Types of Stones:

- Granite: A tough, dense stone that requires primary and secondary crushers such as jaw crushers and cone crushers.

- Limestone: Softer than granite, suitable for impact crushers and hammer mills.

- River Gravel: Often requires crushers with high capacity for consistent and uniform aggregates.

- Basalt: A hard volcanic rock requiring robust crushing equipment like jaw crushers and impact crushers.

Understanding the characteristics of the raw material is essential to choosing the right equipment and ensuring the plant’s efficiency.

2. Production Capacity

The production capacity you need will dictate the size and type of crushers, screens, and conveyors used in the plant. A high-production plant typically requires larger equipment with more power to handle the increased volume of material. For smaller operations, more compact equipment may suffice.

Factors to Consider: